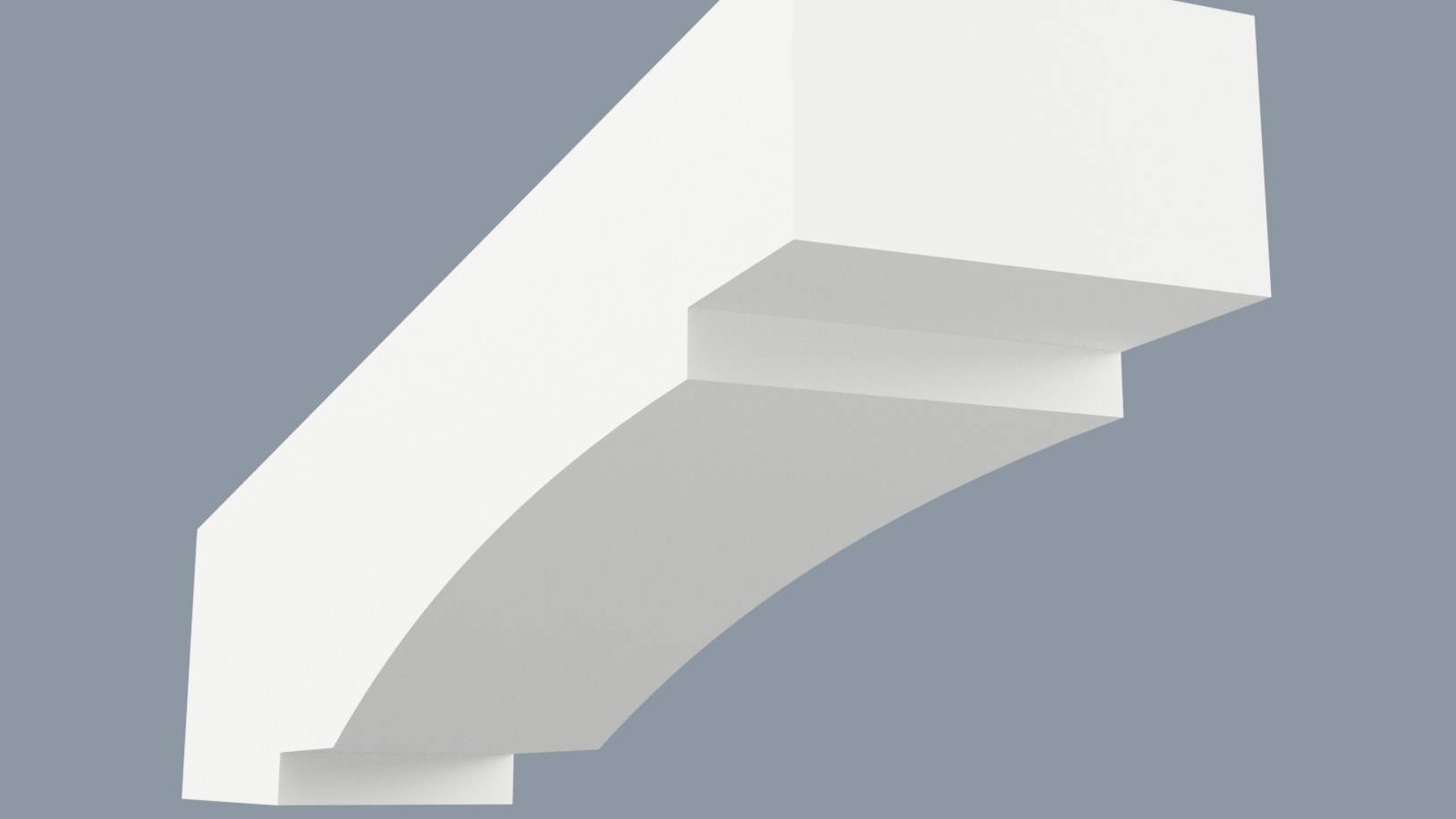

HB RAFTER TAILS

Rafter tails are the exposed exterior portion of a building’s wood structural truss that projects beyond the perimeter wall of the structure. This structural element is secured to the top of the exterior wall or tie beam and then projects to support the soffit overhang. Exposed rafter tails are typically scrolled and detailed and is a major component of the soffit system in timber frame construction. A rafter tail is also considered, depending on where it is used on a home, as an Outlooker, Outrigger, Lookout, or Tailpiece. These components support the soffit system, cantilever deck, or gable end; all of which consist of tongue and groove roof decking and the fascia board or exterior trim board.

| THICKNESS | WIDTH | LENGTH | ||||

|---|---|---|---|---|---|---|

| 12" | 18" | 24" | 30" | 36" | ||

| 3” | 4” | ● | ● | ● | ● | ● |

| 3 ½” | 4” | ● | ● | ● | ● | ● |

| 4” | 4” | ● | ● | ● | ● | ● |

| 5” | 4” | ● | ● | ● | ● | ● |

| 5 ½” | 4” | ● | ● | ● | ● | ● |

| 6” | 4” | ● | ● | ● | ● | ● |

| 3” | 5 ½” | ● | ● | ● | ● | ● |

| 3 ½” | 5 ½” | ● | ● | ● | ● | ● |

| 4” | 5 ½” | ● | ● | ● | ● | ● |

| 4 ½” | 5 ½” | ● | ● | ● | ● | ● |

| 5” | 5 ½” | ● | ● | ● | ● | ● |

| 5 ½” | 5 ½” | ● | ● | ● | ● | ● |

| 6” | 5 ½” | ● | ● | ● | ● | ● |

| 3” | 7 ½” | ● | ● | ● | ● | ● |

| 3 ½” | 7 ½” | ● | ● | ● | ● | ● |

| 4” | 7 ½” | ● | ● | ● | ● | ● |

| 4 ½” | 7 ½” | ● | ● | ● | ● | ● |

| 5” | 7 ½” | ● | ● | ● | ● | ● |

| 5 ½” | 7 ½” | ● | ● | ● | ● | ● |

| 6” | 7 ½” | ● | ● | ● | ● | ● |

| 3” | 9 ½” | ● | ● | ● | ● | ● |

| 3 ½” | 9 ½” | ● | ● | ● | ● | ● |

| 4” | 9 ½” | ● | ● | ● | ● | ● |

| 4 ½” | 9 ½” | ● | ● | ● | ● | ● |

| 5” | 9 ½” | ● | ● | ● | ● | ● |

| 5 ½” | 9 ½” | ● | ● | ● | ● | ● |

| 6” | 9 ½” | ● | ● | ● | ● | ● |

WILL NOT SPLIT, CHECK, CRACK, OR ROT

LOW

MAINTENANCE

SUPERIOR

PAINT

ADHESION

INSTALLED USING TYPICAL WOODWORKING TOOLS

REDUCED INSTALLATION

TIMES

STRAIGHTFORWARD INSTALLATION PROCESS

Portfolio

What are rafter tails?

Rafter tails are the exposed exterior portion of a building’s wood structural truss that projects beyond the perimeter or exterior walls of the structure. This structural element is secured to the top of the exterior wall or tie beam and then projects to support the soffit overhang. The rafter tail are typically scrolled and detailed and is a major component of the soffit system in timber frame construction. A rafter tail is also considered, depending on where it is used on a home, as an Outlooker, Outrigger, Lookout, or Tailpiece. These components support the soffit system, cantilever deck, or gable end; all of which consist of tongue and groove roof decking and the fascia board or exterior trim board. Exposed rafter tails will look perfect when installed in exterior walls.

If you want to learn more about rafter tails we encourage you to watch this video or head over to the HB Elements videos library.

If you want to learn about the installation process of rafter tails, watch this video.

What are HB rafter tails made of?

HB Elements rafter tails are constructed of free foam Cellular PVC. We form these sheets into a limitless amount of rafter tail shapes and sizes. For increased durability and performance, we use our 1/2″ and 3/4″ products that look like actual rafters . In addition, we also use a milled 3/4″ PVC cleat custom made and shipped with each unit sold, which gives the end-user first, no need to create their own cleat on the job site and second great durability after installed from storms and extreme environments even when left exposed. Also, this rafter tails doesn’t affect structural integrity.

How Do I order HB PVC rafter tails?

The ordering of PVC Rafter Tails from HB Elements is a very simple process that has been designed to create convenience. The most commonly used option is, to email us a PDF set of plans of your home or building, then call and discuss with one of our representatives and they will help you select the perfect rafter tail for your needs. You may also pick a rafter tail design from the catalog and a size from the options available and submit an email to [email protected] or you can also use our contact form below.

How long do PVC rafter tails last?

The life cycle of HB Elements PVC rafter tails is a lifetime, but they will require proper installation and maintenance and care. As long as they are not installed incorrectly, used as a structural element, and or painted or finished incorrectly they will have this awesome, low maintenance, very durable, and long-lasting life cycle. Unlike wood brackets or other wood rafter tails, life cycle of a PVC rafter tail is a Lifetime. It should never deteriorate and or need replacement, because of the sheer durability and longevity of the rafter tail core material, Cellular PVC as well as the patented building process we use to fabricate our rafter tails and other components.